Multi function Workstation Customizable

Elution Part

1. A row of 8 liquid injection holes, which can be injected at the same time, and the key liquid can be controlled individually.

2. 5 reagent bottle positions, each bottle is equipped with 4L reagent bottle, that is, it can be compatible with 5 kinds of reagents.

3. The instrument is driven by positive pressure liquid, which is convenient and flexible to control the liquid flow rate.

4. The equipment is equipped with a 96-well plate position, and the plate type is specified by the customer.

5. A 96-well deep-well plate can be placed under the plate to collect the liquid, or it can be directly connected to the pipeline to drain off the waste liquid.

6. In the software part, you can select the type of reagent and the amount of reagent to add samples, the time can be set, the pressure gear can be set, the pressure time can be controlled, and the steps can be set to run continuously. 2 types of recipes.

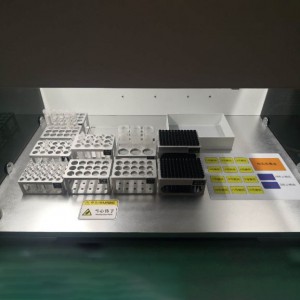

Purification part

1. The equipment can fill up to 96 c18 columns at one time.

2. The standard equipment is equipped with five reagent ports, a centrifuge tube holder, and the holder can carry a maximum of 96 primer centrifuge tubes.

3. The equipment adopts three-axis independent control system, with high precision and good repeatability.

4. The equipment adopts suction filter type.

5. The software settings are flexible and easy to operate.

6. The suction head is equipped with a liquid level sensing device that can automatically sense the liquid level height.

Pipetting part

1. 96-well plate to centrifuge tube.

2. Automatic pipette tip: each primer can be divided into 2 strips at most.

3. X, Y, Z axis movement.

4. The range of suction volume (5-200ul).

5. When dividing into multiple tubes.

6. Time requirements.

7. Can be linked with the measurement template,Error prompt function, there is a pause function in the middle Red indicates that the total volume is not enough and needs to be overlapped.

There are red, yellow and green tips for calculating the volume: yellow means the volume is less, you can manually modify the volume, no need to overlap, green means normal.

8. Information such as column number, number of tubes, and volume of each tube are displayed when filling each sample. The status shows that the primers have been divided and not divided, automatic positioning correction before each dispensing.